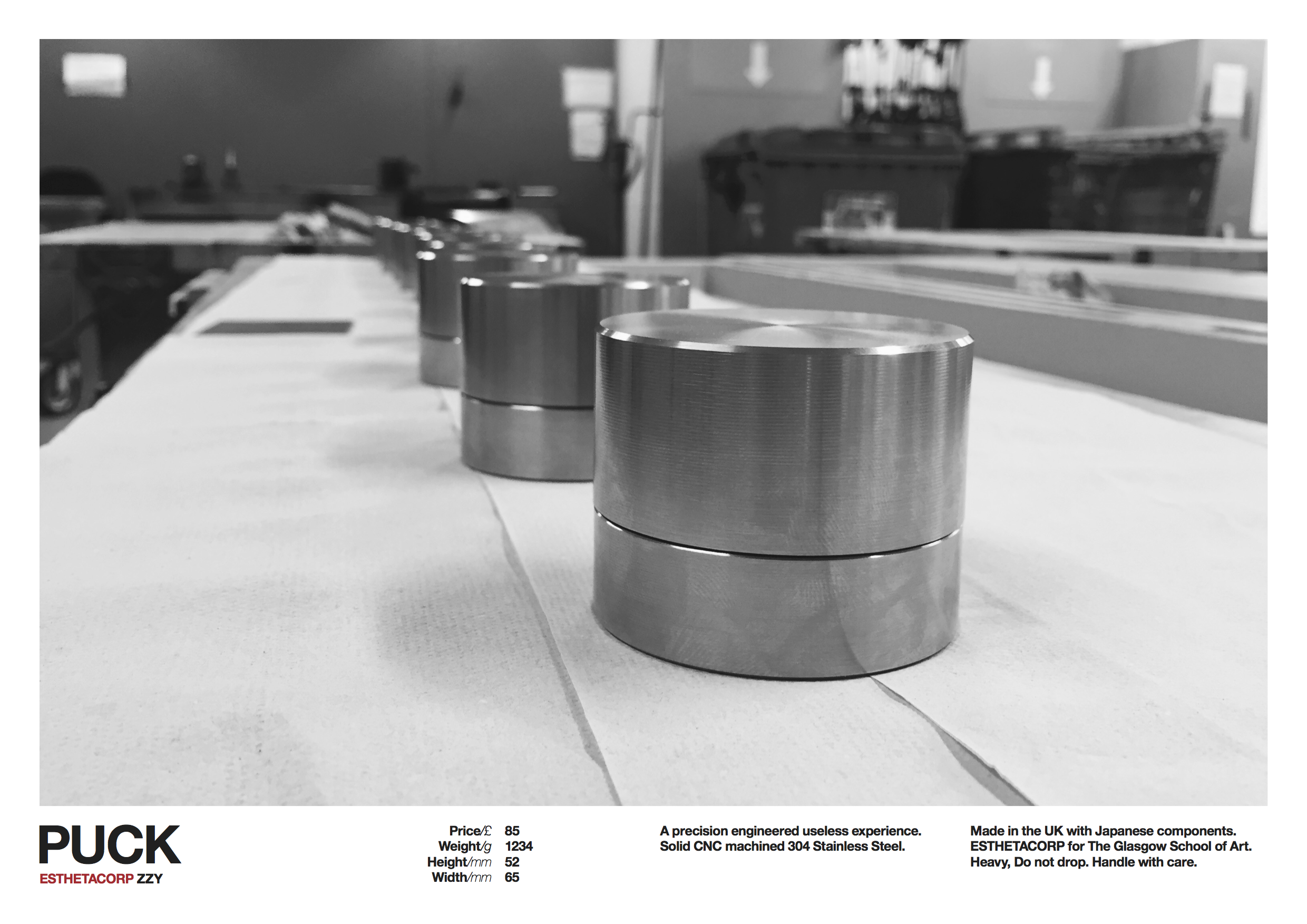

PUCK

ESTHETACORP ZZY

December 2017

Expand Image

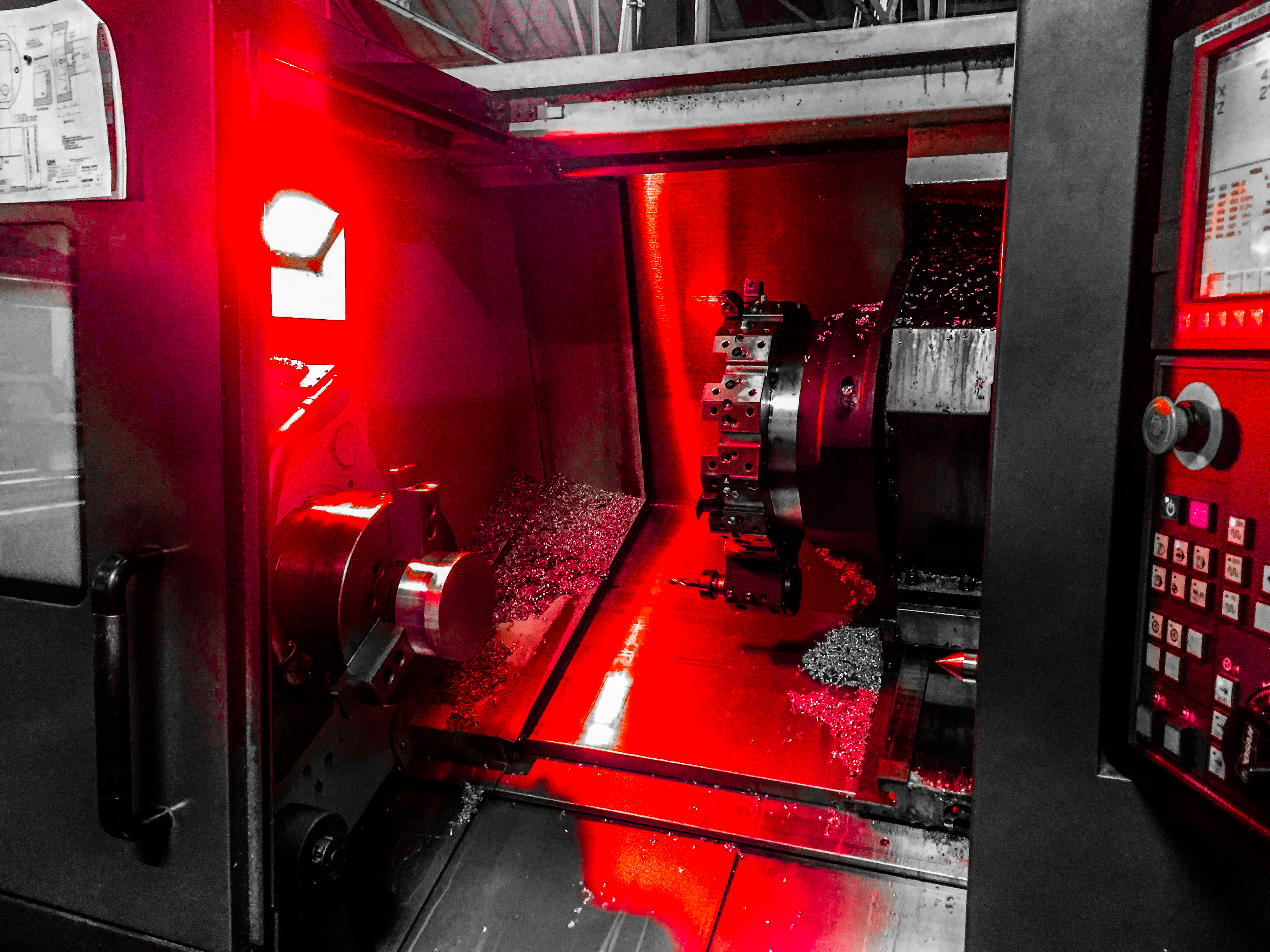

My ambition with this product process was to explore as fully as possible specific manufacturing processes.

Expand Image

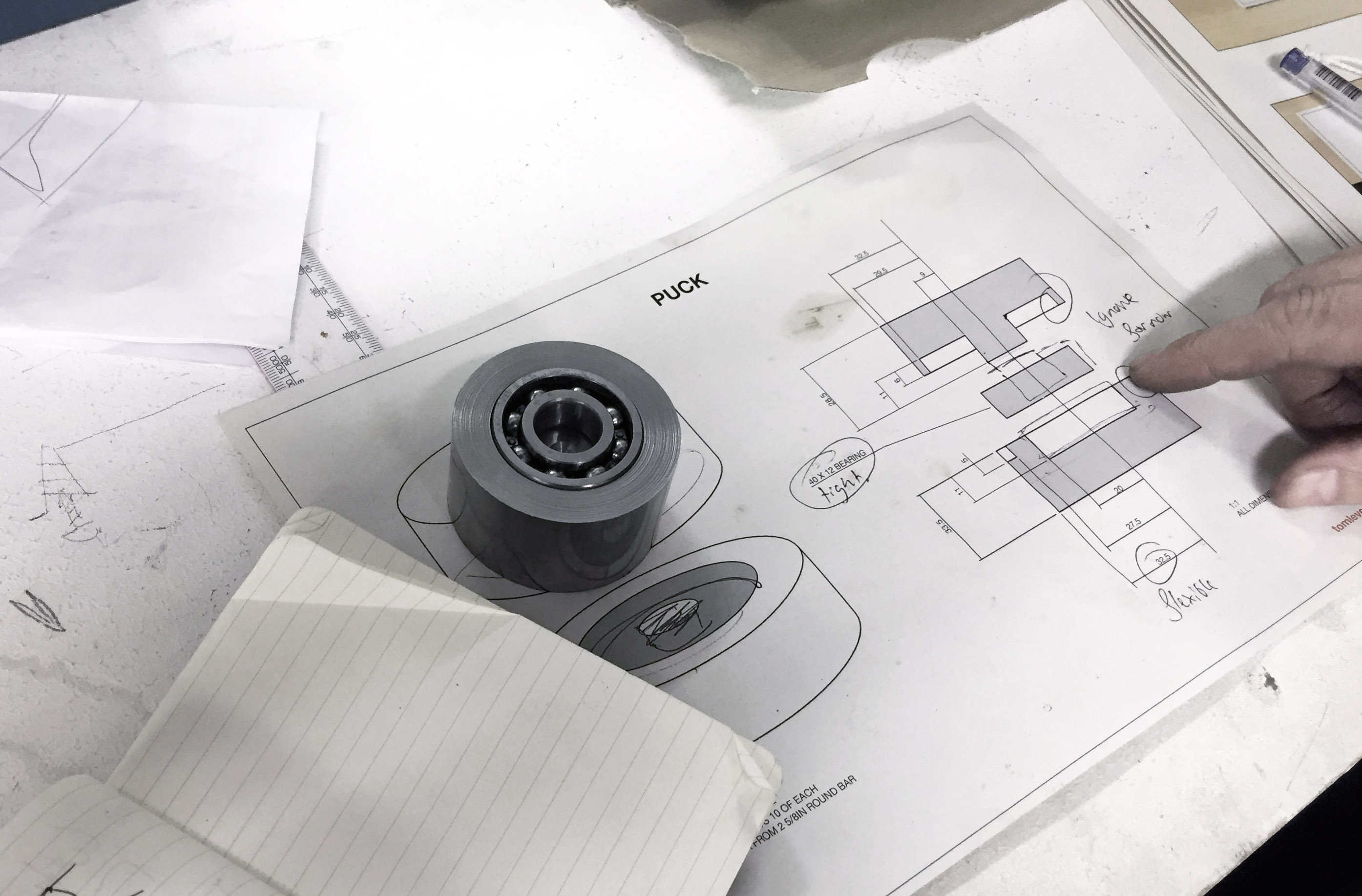

The project involved a lot of technical back- and forth, between me and both the school workshop staff and with me and NPI Solutions who were the professional producers of the final product.

Expand Image

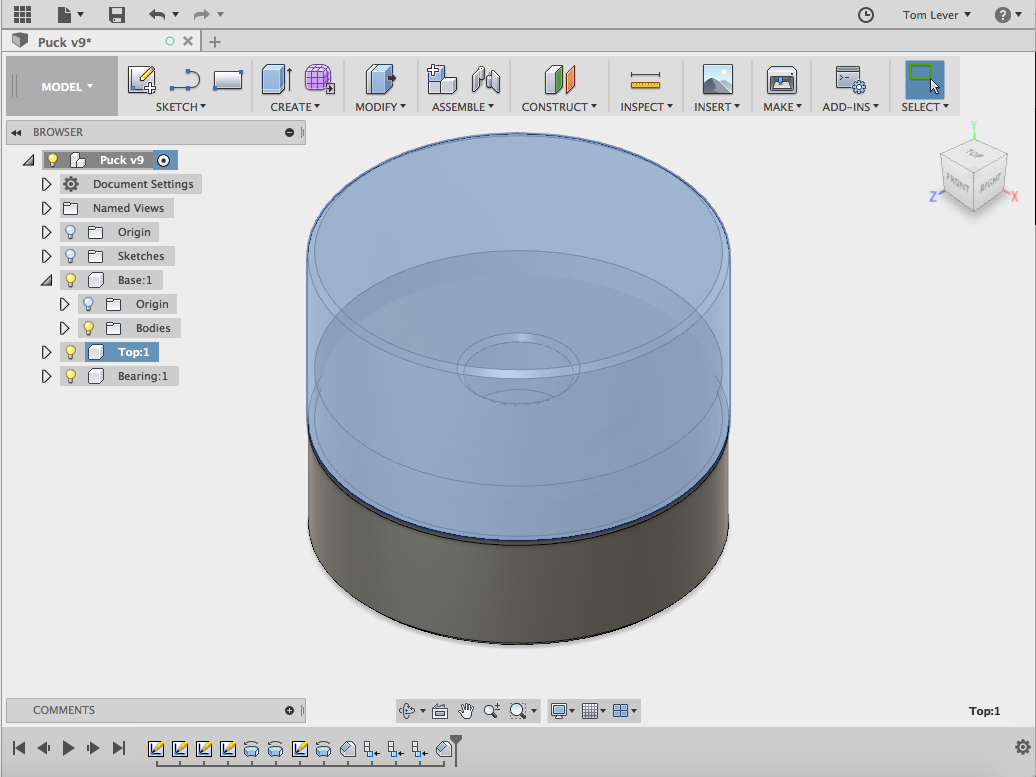

After an initial full prototype was made, I went back to, a fully resolved and well- formatted CAD model was produced and sent to the manufacturer.

Expand Image

The finial design utilises precise detailing and tight fitting to give a satisfying end product.

The central 40mm KOYO bearing is hidden behind a 0.5mm shadow gap, and the 406 stainless steel form framed with careful chamfering.